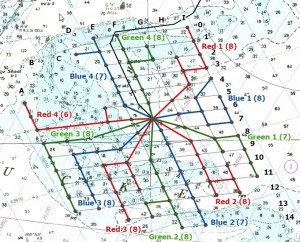

The offshore wind and power grid transmission industry is growing rapidly in Europe, but is still new compared to telecom and Oil & Gas (O&G). While some subsea installation practices and procedures are transferable to the newer Offshore Wind Farm (OWF) industry, many are not. For example, inter turbine array cable, or infield cable, requires unique procedures because of the multiple runs of cable within a confined, precisely planned area of the turbine foundation array.

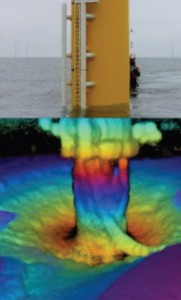

Due to unique physical constraints of OWF arrays and the sensitive nature of the power cable, as well as the repetitive nature of multiple turbine connections, the favored method for inter-array cable burial is PLIB trenching with a tracked vehicle. Additionally, when seabed conditions allow, water-jetting technology is preferred over the potentially more dangerous mechanical cutting.

Our research shows that many burial vehicles will be needed as OWF build rates increase to meet industry projections. If burial equipment is available, its owners will probably be using it in their bid proposals for upcoming jobs. It will be the responsibility of the hiring company to perform sufficient due diligence to ensure that the equipment proposed is the best suited for the job.